1970 Impala Front Suspension Parts Diagram

If I were to guess, I would say that your classic ride is still sporting the factory suspension. That's not necessarily a bad thing, but can I ask why? Is your car an OE-type restoration? Maybe, you think the ride it delivers is okay? Whatever the reason, I'm here to tell you that updating your classic Chevy's underpinnings is a great idea. But what if your classic was originally marketed as one of the "luxury" models? What I mean is, what if your classic delivered the smoothest ride available from Chevrolet in the mid-to-late '60s? Is that still good enough? What if your car is an Impala, Bel Air, Caprice, or Biscayne, and was never meant to be a performance car? As many enthusiasts can attest, never say never…

After decades of racking-up miles, it's probably time to upgrade. Inserting spring supports into the coil spring does not constitute adjustable ride height.

We recently got an announcement from the folks at QA1, heralding the introduction of new suspension upgrades for the '65 through '70 Chevrolet Impala, Caprice, Belair, Biscayne. I know what you're thinking, "why would anyone want to make an Impala handle like a sports car"? It's understood that late-model sports cars are a different breed of hot rod when compared to this 50-year old heavy Chevy. But the upgrades will definitely help you see some significant performance gains that will help your classic keep up with them on twisty back roads. To do so is easy. Simply take the outdated and maybe even worn suspension and bring it into the 21st century. This isn't something to do just for the sake of doing something. Upgrading has serious benefits for the car owner. "I was amazed at the transformation after installing the QA1 kit on a few of these cars," says Dave Kass of QA1. "It felt like we removed a couple thousand pounds from the car. The suspension's ability to control the massive 4,000-plus pounds was impressive."

Before we begin, we have to face facts, GM B-bodies were never designed to be heroes of the autocross circuit. Doing so is akin to asking a 4,000-pound Barcalounger to pull some serious Gs on the skidpad. Not only is that a tall order, but wow, is it even possible? Within reason, yes.

Before you begin disassembly of the old parts, it would be a wise idea to hit all the fasteners with a good penetrating oil. According to Dave, "having a good rust penetrant on hand and a few hours for it to do its job wouldn't be a bad idea. Outside of that, a normal inspection of brakes, wheel bearings, and other service items might be something to consider checking before tearing everything down. Replacing these items during the project doesn't add much time while reducing later downtime for service work."

When the big B-bodies left the factory, the suspension consisted of coil springs and shocks on all four corners, stamped steel control arms, and gas-charged shock absorbers. When these cars were new, this was the best GM had to offer, and it was great at creating a comfortable ride for the general public. While keeping any car comfortable when cruising is paramount for most enthusiasts, many still want it to handle better than marbles on mashed potatoes. This is where the QA1 bolt-on parts come into play.

Installing More Control

"Modernizing the suspension of a 50-plus-year-old vehicle has huge, positive effects on drivability," Dave affirms. "With modern cars being so good from the factory, the shortcomings of these early cars really show. Couple that with worn components and years of abuse, and it's readily apparent there are great gains to be had. This kit really modernizes the feel and overall driving experience."

But what about the actual installation? Can the average enthusiast do this in their garage or driveway? "Installation is really straight forward," Dave states. "I don't anticipate any major hangups that need to be overcome. We have published front and rear installation videos for this on our YouTube channel, and it's easy to see just how easy this can be. Basic hand tools and a Saturday afternoon is all you need to successfully install these items."

Modernizing the suspension of a 50-plus-year-old vehicle has huge, positive effects on drivability. – Dave Kass, QA1

The kits are available in six different configurations across three increasing performance levels for either drag racing or handling performance. Depending on the intended use, the kit will include:

- Single or double-adjustable coilovers provide up to a 2 1/2- inch drop in the front and a 4-inch drop in the rear, allowing you to dial in the perfect stance. Adjustable Proma Star shocks enable tuning the ride to the ideal comfort and performance level.

- Tubular control arms provide a much more modern driving feel. With up to 5 degrees of caster and -1 degree of camber (goes down the road with less wandering), this simple upgrade will modernize your 55-year-old suspension. Remove the flexibility of the OE design for predictable handling and straight-line stability.

- Trailing arms have a unique adjustable upper mount that provides significant tuning of the vehicle's anti-squat, resulting in better traction. Equipped with greasable polyurethane bushings, fixed lowers are much stronger and stiffer than OE. Optional adjustable uppers provide perfect pinion angle adjustment. Available for both three- and four-link cars.

- Sway bars are specifically designed for the B-body chassis. These bolt-in sway bars reduce body roll to create better vehicle response and improved handling performance while cornering. Front sway bars 1-3/8- or 1-1/4-inch diameter and provide required stiffness and reduce weight. 1-inch diameter rear bar provides the desired tuned balance with the other components.

- A full-length adjustable Panhard bar is essential for dialing in the correct position to reduce lateral axle movement during cornering while fitting the largest tire possible.

By adding coilovers to replace the shock and coil spring suspension, you have added ride height adjustability, shock dampening tunability, and ultimately, better control of your ride.

Complete Support

Starting with the coilovers, The main reason for this change is to offer suspension adjustability and control. If you don't think this is a big deal for your car, maybe you should reconsider that thought process. Does your car feel like it's floating while driving down the road? Is that actually a good thing? While that might translate into a comfortable ride, there are a few reasons that might not be the best driving condition. When your car is "floating," it is difficult to control how it reacts to road conditions or, shall we say, a surprise situation. Take for instance a panic stop. If your car is "floating" down the highway, the stopping distance can be longer than you actually have available to you. By having a suspension that better controls the car, you will shorten that distance exponentially.

Another part of the QA1 upgrade is a set of tubular control arms. We've all heard talk about these all-new suspension parts, but do tubular control arms actually make a difference in a car's ride and cornering capabilities? Basically, are tubular control arms actually worth your time to install? And more importantly, worth spending your hard-earned cash to buy? In a nutshell, most enthusiasts think so.

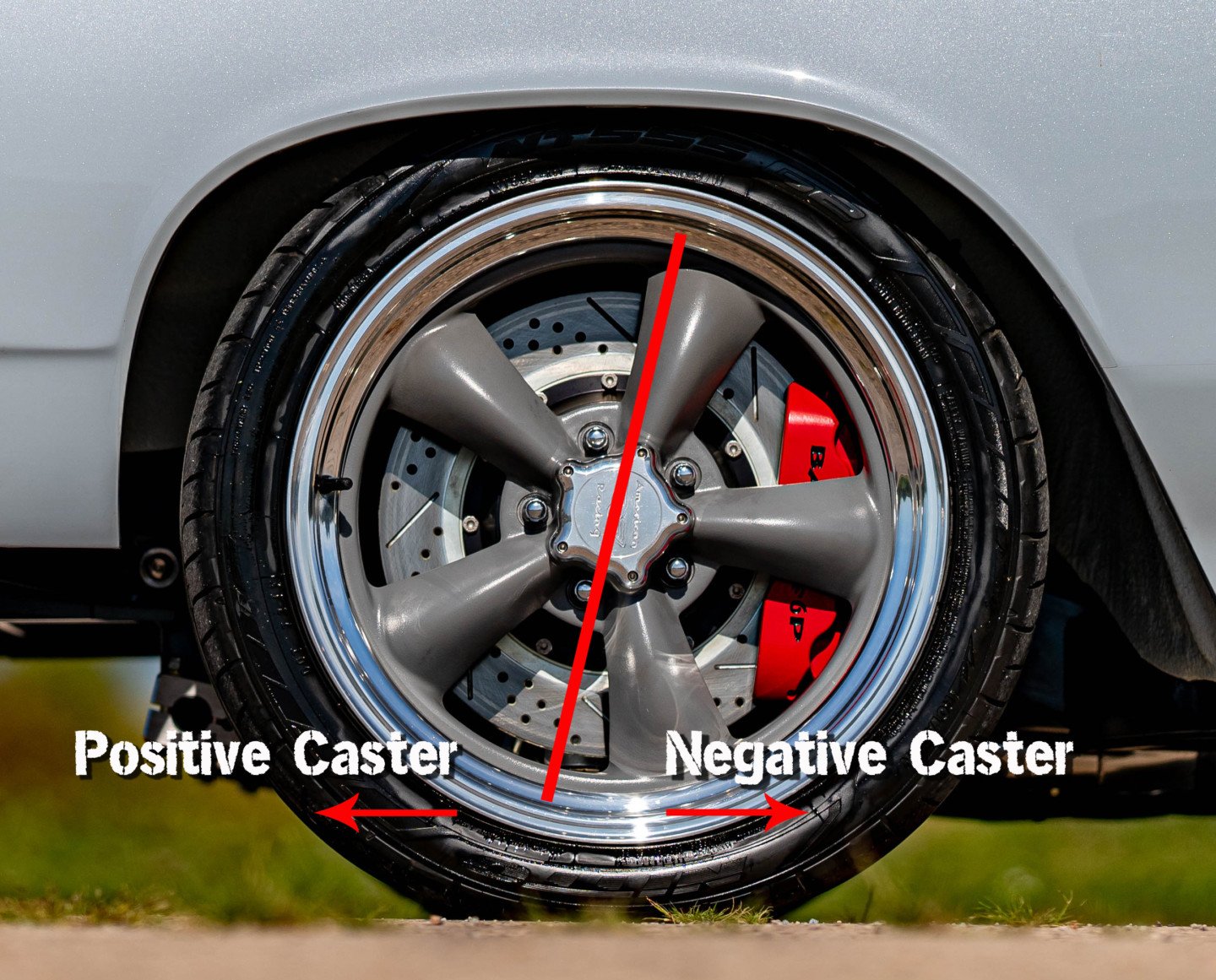

There is one major reason to use tubular control arms. These parts help with caster and camber. When someone talks about camber, they are referring to how much the top of the tire leans in or out. Caster is a little harder to identify when looking at a car because it is the angle of an imaginary line that is measured through the top and bottom ball joints.

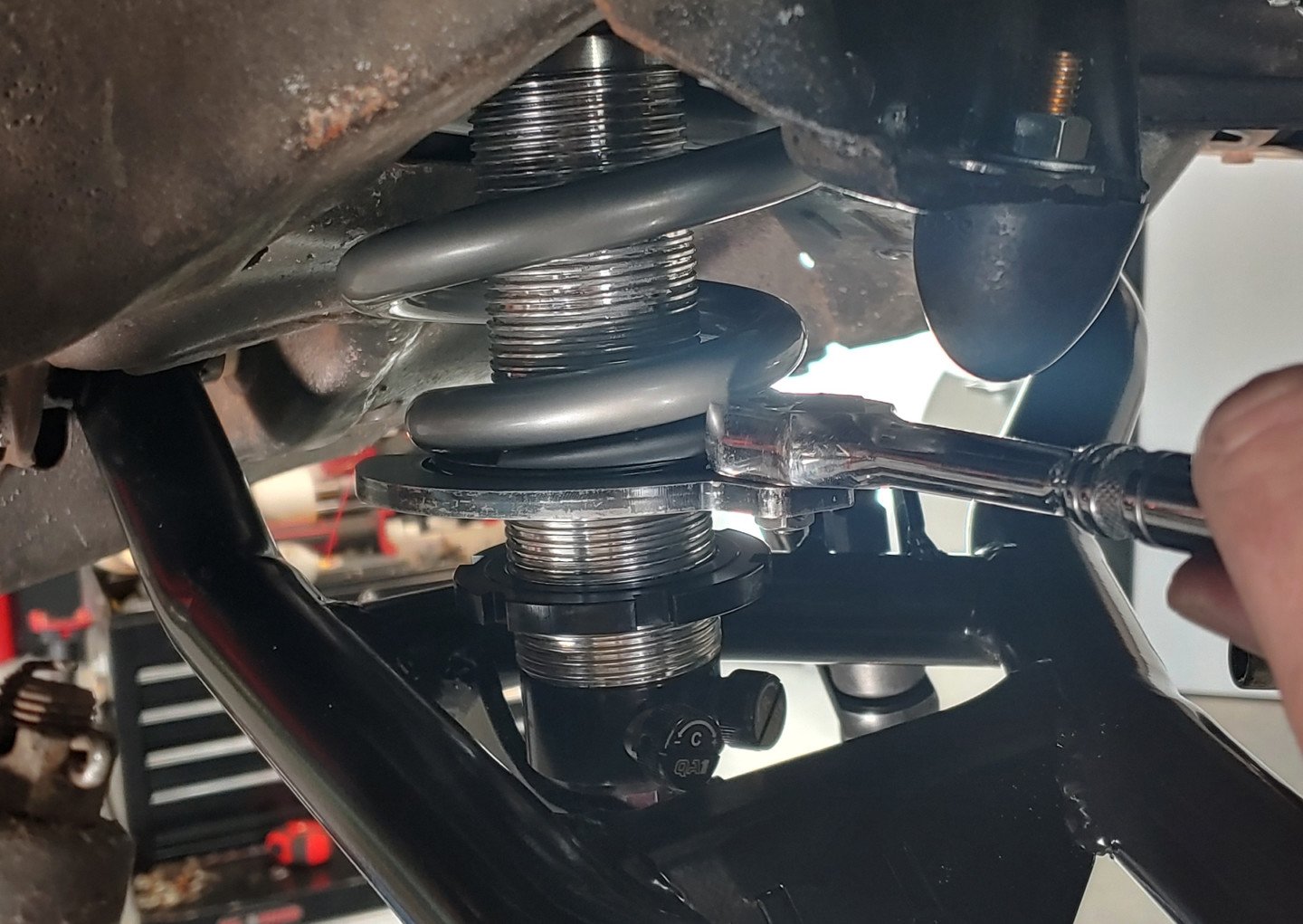

QA1 upper and lower control arms are designed to add more caster and negative camber. It is a good idea to make the alignment shop aware of this, as the alignment shop will only try to align the vehicle to factory specs. The majority of the alignment adjustments for the '65-'70 full-size cars are done at the lower control arm (right). If needed, shims can also be added to the upper control arms to adjust caster and camber.

Proper camber is critical to keeping tires planted on the road. When driving your car and encountering a turn, what needs to happen is the front wheels need to lean (slightly) to help keep the tires planted. However, With many OE suspensions, this doesn't happen. In essence, when you take that turn, the wheels lean very little, not at all, or even outward. When this occurs, traction is limited. Have you ever slid through a corner because of taking it too fast? This is a major contributor.

Positive caster positions the lower ball joint in front of the upper ball joint. This results in the tire contact patch hitting the ground in front of the centerline of the steering system and suspension components. A negative caster places the lower balljoint behind the centerline.

The OE control arms are not actually a bad design. We just need to keep in mind that when they were designed years ago, cars used bias-ply tires that could not handle the way a radial tire can. Without getting too technical, bias-ply tires are "happier" with less caster. Radial tires, on the other hand, are just the opposite.

But what is wheel caster? This alignment specification is best described as an imaginary line that goes from the top ball joint through the lower ball joint. It's this "angle" that helps keep your car going straight when driving down the road. Positive caster creates a "force" that wants to return (keep) the front wheels pointed straight ahead while at speed. You experience the benefits of positive caster every time you release the steering wheel after turning and the steering wheel returns back to 12 o'clock after exiting a corner. Without positive caster, the vehicle would also want to wander at highway speeds. The easiest way to accomplish this is by utilizing tubular control arms with modern geometry built-in, because there is no number of shims that can safely be used on a stock control arm that will get the geometry corrected to modern standards.

Finally, the QA1 sway bar will be the finishing touch. Sure, most of these big cars came factory equipped with a sway bar, but once again, modern components can make a huge difference in a car's suspension. The sway bar is just a metal bar that ties the driver- and passenger-side chassis and suspension together. When a car is traveling straight down the road or track, a sway bar has little effect on handling. However, as soon as you turn the steering wheel, the car wants to lean. The sway bar is actually a spring that helps control the weight shift (lean) that occurs when cornering.

The primary differences between your car's stock sway bar and a QA1 sway bar are stiffness and weight. In the world of sway-bar upgrades, bigger might seem to be better. But can they be too big? Do you even need a sway bar? These are just a couple of questions you might be asking yourself about these suspension-supporting bars.

This front sway bar uses a base plate mounted to the frame before the sway bar is mounted. Installation of the plate will require drilling.

For starters, are larger sway bars better? According to the QA1 website, in most applications, yes. When you start adding bigger and stickier tires, upgraded shocks, and enjoy more aggressive driving, your car or truck can benefit from bigger sway bars. You might be asking yourself, "why should I consider a sway bar upgrade? For starters, factory sway bars could be worn out or simply not up to par. When you install modern (radial) tires that maintain more traction and you push the car more when entering a corner, the car will want to sway/roll more. In most applications, there isn't even a factory sway bar in the rear, so this leaves a lot of room for a huge improvement.

Next comes the sway bar.

Installing a front sway bar is one of the easiest upgrades you can do for your suspension. Upgrading to QA1 bars is a job that usually only takes an hour or two with basic hand tools. This makes this an easy upgrade for a drastic change in your suspension. If you're concerned upgrading sway bars might create a stiffer ride, even a well-engineered sway bar can. However, a sway bar should complement the suspension and not overpower it. Remember, bigger is not always better — you can go too big! If you go too big, the suspension might not be able to twist/flex the sway bar properly, which would result in a stiff ride.

The most visually noticeable aspect of the kit is the ride height adjustability afforded by the coilovers.

When driving down the road, a sway bar has little to no effect on how soft or firm your car rides. That is where spring rate, shock valving, and tire sidewall size come into play. The spring rate of the sway bar only comes into effect when cornering, when it helps to reduce or eliminate body roll.

Talking about ride height, once you have it at that perfect stance, an alignment will be required. Also, any time you change ride height, another alignment will be needed.

When the big B-body cars rolled off the assembly line, they were designed to be the family cruiser that offered a nice ride. Now, it's several decades later, and with the help of QA1, your big car can maintain a nice, controllable ride and still corner like its sportier counterparts that spend time at the many autocross tracks around the country. According to Dave, "after installation, I would suspect someone will be putting many more miles on the car than they did previously. Being much more fun to drive, yet comfortable, road trips will be much more enjoyable."

Source: https://www.chevyhardcore.com/tech-stories/brakes-suspension/65-70-impala-bel-air-biscayne-and-caprice-suspension-upgrade/

Posted by: sheliasheliadunnavillee0270335.blogspot.com

Post a Comment for "1970 Impala Front Suspension Parts Diagram"